As the world becomes increasingly automated, more and more jobs are being replaced by machines. In some cases, this is a good thing – after all, who wouldn’t want to be replaced by a machine? But in other cases, the loss of jobs can be devastating, as entire industries are wiped out. One such industry is trucking.

Self-driving trucks are already a reality, and they’re only going to become more common in the years to come. This is bad news for truckers, as their jobs will soon be obsolete. But it’s also bad news for warehouse workers, as the self-driving trucks will need to be unloaded – and that’s a job that is currently done by humans.

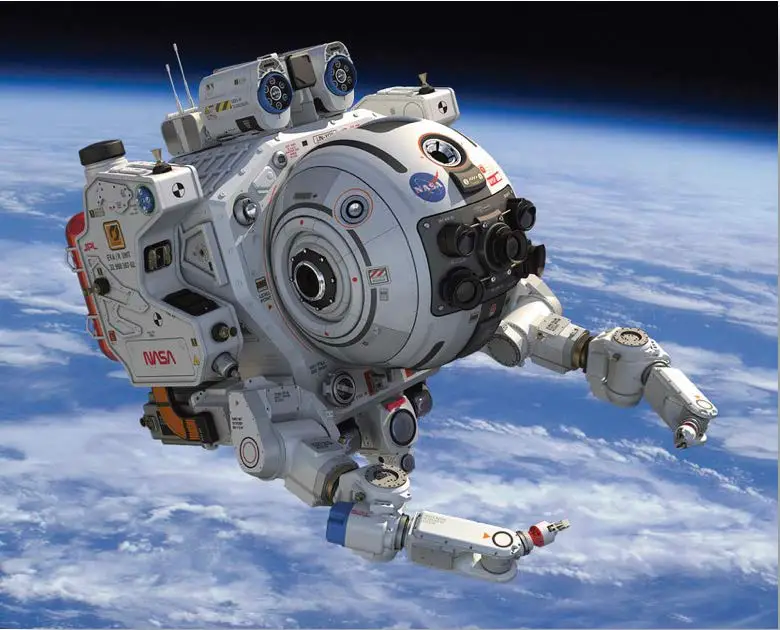

Enter the unloading robot. These robots are designed to unload cargo from self-driving trucks, and they’re already being used in some warehouses around the world.

The unloading process is simple: the robot grabs a pallet of cargo from the truck, and then brings it into the warehouse. Once the pallet is in the warehouse, the robot sets it down and unloads it.

The benefits of unloading robots are obvious. They’re faster than humans, and they never get tired. They can also work 24 hours a day, which means that they can unload cargo even when the warehouse is closed.

Perhaps most importantly, unloading robots can help to prevent injuries. Warehouse workers are often injured by lifting heavy pallets of cargo, but unloading robots don’t have that problem.

So far, unloading robots have been a success. They’re efficient, they’re safe, and they’re only going to become more common in the years to come. So if you’re looking for a job in the warehouse industry, you might want to consider becoming an unloading robot operator.

What is unloading robot cargo package and how it works

In a world where self-driving cars are becoming more and more common, it was only a matter of time until unloading robots made their debut. These robots are designed to unload cargo from self-driving trucks, and they’re already being used in some warehouses around the world.

How does unloading robot cargo package work?

The unloading process is simple: the robot grabs a pallet of cargo from the truck, and then brings it into the warehouse. Once the pallet is in the warehouse, the robot sets it down and unloads it.

What are the benefits of unloading robot cargo package?

There are many benefits of unloading robots, including the fact that they’re faster than humans, they never get tired, and they can work 24 hours a day. Additionally, unloading robots can help to prevent injuries as they do not lift heavy pallets of cargo like human workers do.

The benefits of unloading robot cargo package

There are many benefits of unloading robot cargo package, including the following:

1. They’re faster than humans – unloading robots can unload cargo much faster than human workers can.

2. They never get tired – unloading robots can work 24 hours a day, seven days a week.

3. They can help to prevent injuries – because unloading robots don’t have to lift heavy pallets of cargo, they can help to prevent injuries in the warehouse.

4. They’re efficient – unloading robots are designed to be as efficient as possible, which means that they can help to save the company time and money.

5. They’re safe – unloading robots are much safer than human workers, as they don’t have to worry about getting injured while lifting heavy cargo.

Overall, unloading robot cargo package have many benefits that make them an appealing option for warehouses around the world.

How unloading robot cargo package is changing the shipping industry

As the world becomes increasingly more automated, so too does the way we ship and receive packages. Unloading robot cargo package has become an essential part of warehouses and shipping operations. Here’s how it works:

First, a unloading robot is stationed in a designated area near the shipping dock. Once a package is delivered, the unloading robot will scan the package and then load it onto a conveyor belt.

The unloading robot will then unload the package from the conveyor belt and place it in a designated storage area. This process is repeated until all packages have been unloaded.

Unloading robots are changing the shipping industry because they provide a faster, more efficient way to unload packages. They also help to reduce labor costs and improve safety by eliminating the need for workers to be in close proximity to heavy machinery.

Unloading robot cargo package is a new and efficient way to unload packages in a warehouse or shipping setting. The unloading robot quickly and safely unloads packages from a conveyor belt and into a designated storage area. This process reduces labor costs and helps to improve safety by eliminating the need for workers to be in close proximity to heavy machinery. Unloading robot cargo package is changing the shipping industry by providing a faster, more efficient way to unload packages.

If you are looking for a new and efficient way to unload packages in your warehouse or shipping operation, unloading robot cargo package may be the perfect solution. This technology quickly and safely unloads packages from a conveyor belt and into a designated storage area, helping to reduce labor costs and improve safety in your facility. Thanks to unloading robot cargo package, the shipping industry is changing for the better by providing a faster, more efficient way to unload packages.