There is a lot of talk these days about the cost-effectiveness of robots in the workplace. A lot of people seem to think that replacing human workers with robots will save companies money in the long run. But is this really true? Is it really cheaper to use robots instead of human workers? Let’s take a closer look at the cost of using robots vs human workers to unload cargo containers.

There are two main ways to unload a cargo container: by hand or by machine. The most common way to do it is by hand, using a team of workers known as “lumpers”. Lumpers are strong men (and women) who are paid by the hour to unload cargo containers. They are usually paid relatively low wages prior the pandemic and they don’t receive any benefits, which are most often contract based work.

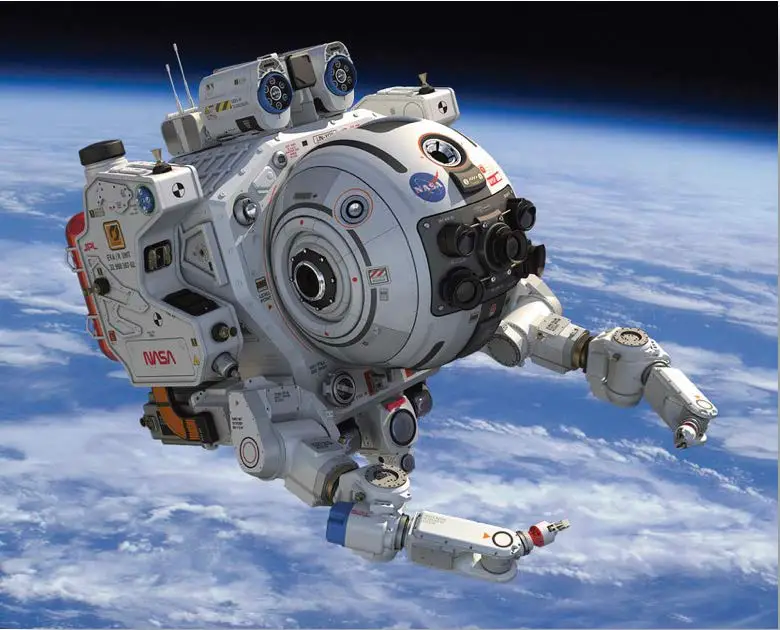

The second way to unload a cargo container is by using some sort of automation. Robots are becoming more and more common in the workplace, and they are often used to replace human workers especially in auto manufacuturing and 3PL logistics.

So, which is cheaper? Is it cheaper to use robots or human workers to unload cargo containers?

There are a few factors that need to be considered when answering this question. First of all, the cost of the robot itself must be taken into account. Robots often cost a lot of money takes along time to setup, so they need to be heavily subsidized by the company in order to make them financially viable. And even if a robot is cheaper than using human workers, it may not always be worth the investment due to operating costs, maintenance costs, and other associated expenses.

In addition, the cost of training must be considered. Robots need to be programmed and maintained, which requires specialized skills and knowledge. This training can be expensive, and it may not always be available.

Finally, the quality of the work must be considered. A lot of people believe that robots can do a better job than human workers when it comes to unloading cargo containers. However, there is no real evidence to support this claim. In fact, some studies have shown that human workers have a much lower error rate than robots when it comes to moving and loading cargo.

So, which is cheaper: using human workers or robots for unloading cargo containers? While it’s difficult to say for sure, it seems that using human workers is still the cheaper option prior pandemic but things have shifted dramtically since. Cost of general labor has risen 30% since and it is now comparble to some multi purpose robots.

The cost of using a lumper vs robot to unload a cargo container

When it comes to the cost of unloading cargo containers, there is no clear winner. Both lumpers and robots have their pros and cons, and the final decision depends on the specific needs of the company in question and the loads they are handling at each facility per month. If a company is handling more than 25 loads per month, Arc mobile unloading robots is a great solution to check out.

Pros and cons of using a lumper vs robot to unload a cargo container

Lumpers are relatively cheap to hire, and they don’t require any specialized training. They are usually paid by the hour, so their wages are relatively low. However, using human workers can be more expensive in the long run, due to the costs of training and maintaining them. Prior, robots on the other hand, are expensive to purchase and maintain, but now we are capable of providing businesses robotic as a subcription model which have very comparable cost.

When it comes to quality, it is difficult to say which option is better. Some believe that robots are more precise and have a lower error rate than human workers. Others believe that human workers are better at understanding complex tasks and can adapt to changing situations more easily. Ultimately, the decision comes down to the specific needs of the company.

Which is cheaper – lumpers or robots ?

When it comes to cargo container unloading, there are two main methods: using lumpers or robots. Both have their pros and cons, but which is the cheaper option?

Lumpers are people who manually unload cargo containers. They can be more expensive than robots, but they offer the advantage of being able to work in a variety of different environments. Robots, on the other hand, are highly efficient and can unload cargo containers quickly without needing breaks or requiring a specialized working environment.

However, there are some downsides to using robots for this task as well. They tend to be more expensive than lumpers, and can sometimes have difficulty navigating complex environments and odd dimensions where cargo containers need to be unloaded. Additionally, if a robot breaks or is damaged, it can be costly to repair or replace.

Ultimately, the choice between lumpers and robots comes down to what is most important to you – speed, efficiency, or cost. If you have volume cargo containers to be unloaded quickly and reliably, then cargo unloading robots may be the better option. However, if you are working on a budget and don’t require the fastest possible unloading time, then lumpers may be a more cost-effective choice. In either case, it is important to consider the unique needs and requirements of your business when making this decision.

When it comes to the cost of unloading cargo containers, there is no clear winner. Lumpers are cheaper than cargo unloading robots in the short-term, but robots are more efficient and can save money in the long run. It ultimately depends on the needs of your business and how much time and money you want to spend on unloading containers and most important of all is the volume of unloads your business is handling on a constant basis.